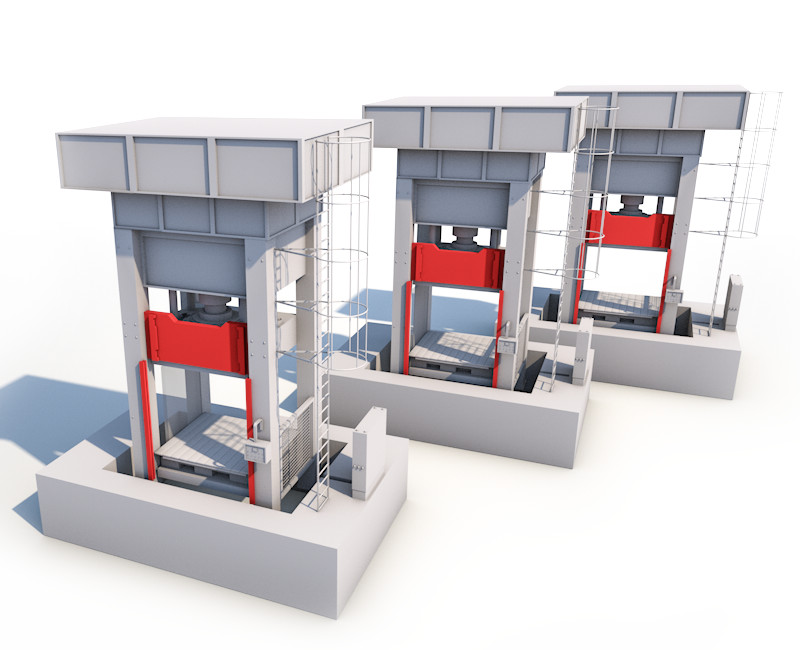

Operations:

This line is designed for the thermoforming of sandwich material, textiles and thermoplastics. A frame, with spikes mounted on a rail, crosses the three machine stations of the production line. The frame is used for the material transfer. This transfer between the stations is manually actuated. Three frames are permanently installed in the machine, and allow a continuous running.

The material heating:

The operator manually transfers the frame under the infrared heating device. During this working cycle step, the material is heated between two panels, regulated on 72 zones. An extractor, integrated in this station, extracts outward the generated smokes.

Forming and cooling:

On the last working zone, the heated material is thermoformed under the press between the two moulds shapes, which are watercooled. This production process with transfer, material infrared heating device and thermoforming is well-know and often used on composite industry.

Français

Français